Enhanced incineration ash accessory for STEINERT's non-ferrous metal separators

The Revolutionary STEINERT Splitcontrol: Optimizing Sorting Quality for Goods and Wastes Alike

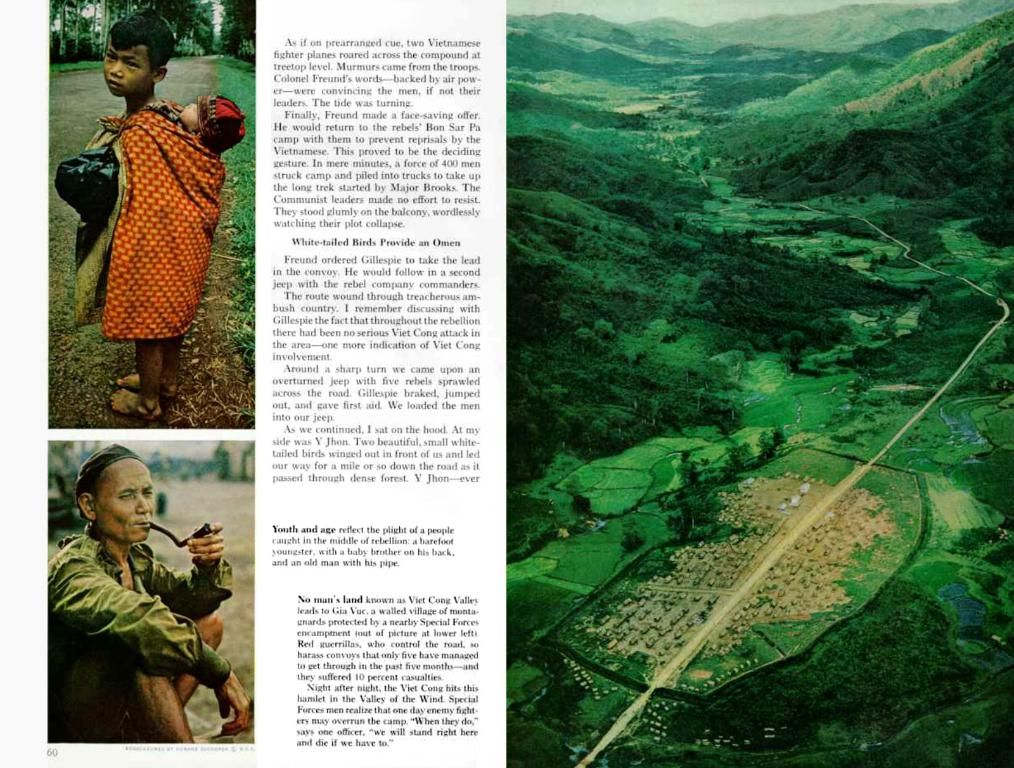

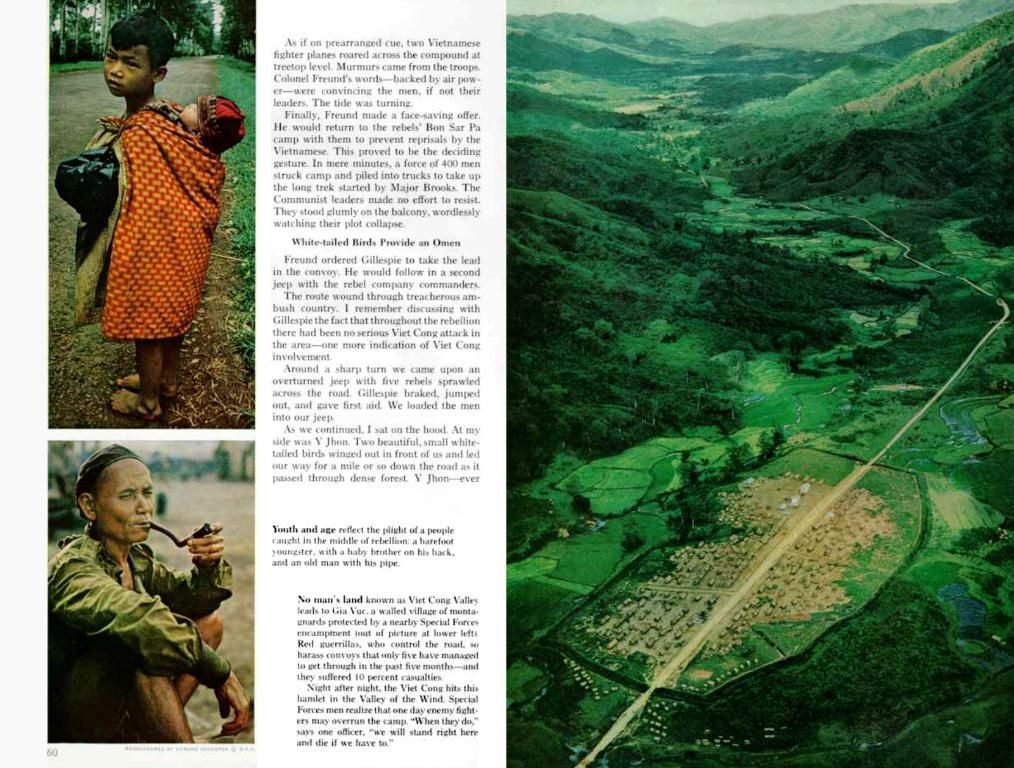

Stepping up its game in the sorting industry, STEINERT introduces Splitcontrol, a cutting-edge technology designed to enhance the quality of sorted products across various applications, ranging from incineration bottom ash to non-ferrous metals. This innovative addition to STEINERT's eddy current separators offers a solution to overcome challenges posed by dynamic material properties such as residual moisture, grain shape, or conductivity.

How Splitcontrol Changes the Game in Sorting

At the heart of Splitcontrol is a laser grid that keeps a watchful eye on the product variance in the discharge zone of the eddy current separator. By proficiently distinguishing the discharge parabolas for conductive non-ferrous metals and non-conductive residue (drop), the system automatically controls the belt speed to maintain the optimal distance between the drop portion and the separating splitter. This meticulous adjustment ensures the sorter consistently achieves peak separation performance.

** Benefits Worth Noting**

- Optimum Quality Guaranteed: With the automated control function, Splitcontrol ensures a steadily high level of sorting quality that adapts to material variations. This steady state guarantees optimal metal yield under all circumstances.

- Reliable and Stable Production: By minimizing human errors, Splitcontrol reduces the risk of subjective, incorrect manual adjustments, leading to overall improvements in operational reliability and stability.

- Reduced Operational Effort: The need for manual interventions to correct the splitter is significantly reduced, freeing up staff for more critical tasks.

- Scalability and Integration: Up to four eddy current separators can be easily managed through a single Splitcontrol unit, making it the perfect choice for streamlined systems.

A Snap to Install and Maintain

Thanks to its compact design and easy-to-install components, the Splitcontrol kit can be set up in just a few hours. The external structure allows for simple installation with minimal modifications to the outer shell. Maintenance and cleaning are straightforward tasks, thanks to the removable housing that allows external access, ensuring the system remains operational with minimal downtime.

In essence, STEINERT's Splitcontrol is the perfect choice for those seeking the highest level of sorting precision and efficiency across a wide variety of applications. The technology combines advanced sensors with intelligent data processing and robust material handling to deliver consistent sorting results while keeping operational costs in check.

- The revolutionary Splitcontrol technology, introduced by STEINERT, brings a significant shift in the industry, offering solutions for optimization in the finance and technology sectors, as it helps improve sorting quality for goods and wastes alike.

- By automating the control function, Splitcontrol seamlessly integrates finance, technology, and the sorting industry, delivering an efficient, reliable, and cost-effective solution that guarantees optimum quality, minimizes operational effort, and ensures scalability.