Exploring the Role of Enhanced Reality in Facilitating Industry 4.0 Transition

Hopping on the AR Wave: Revolutionizing Industries with Augmented Reality

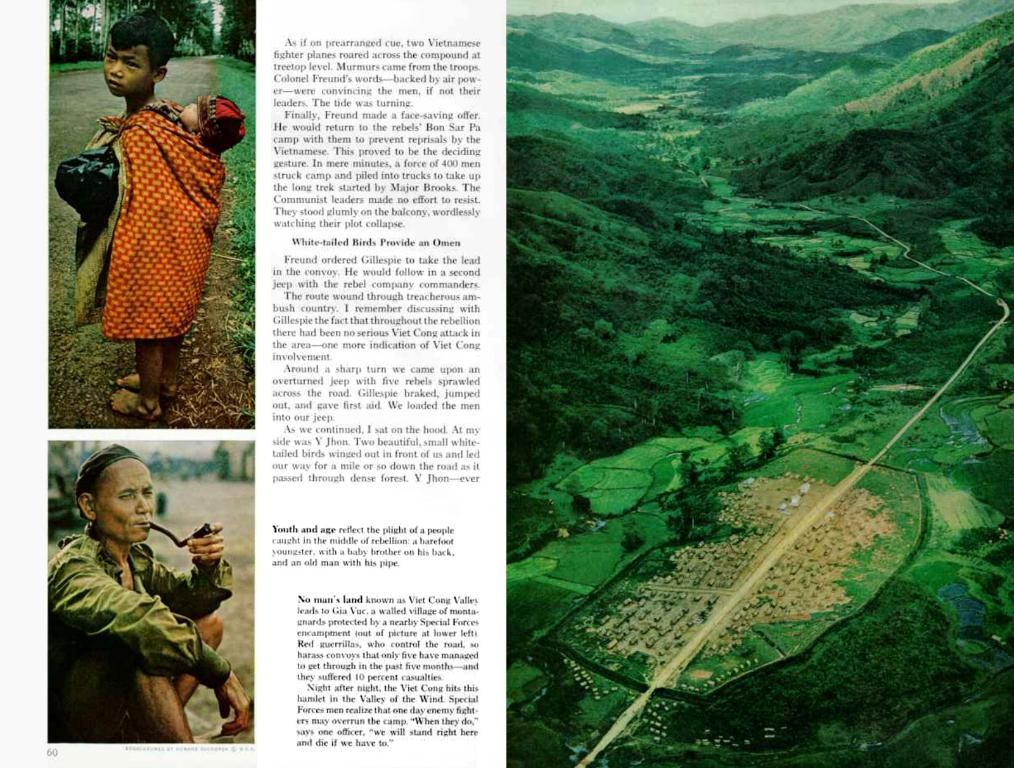

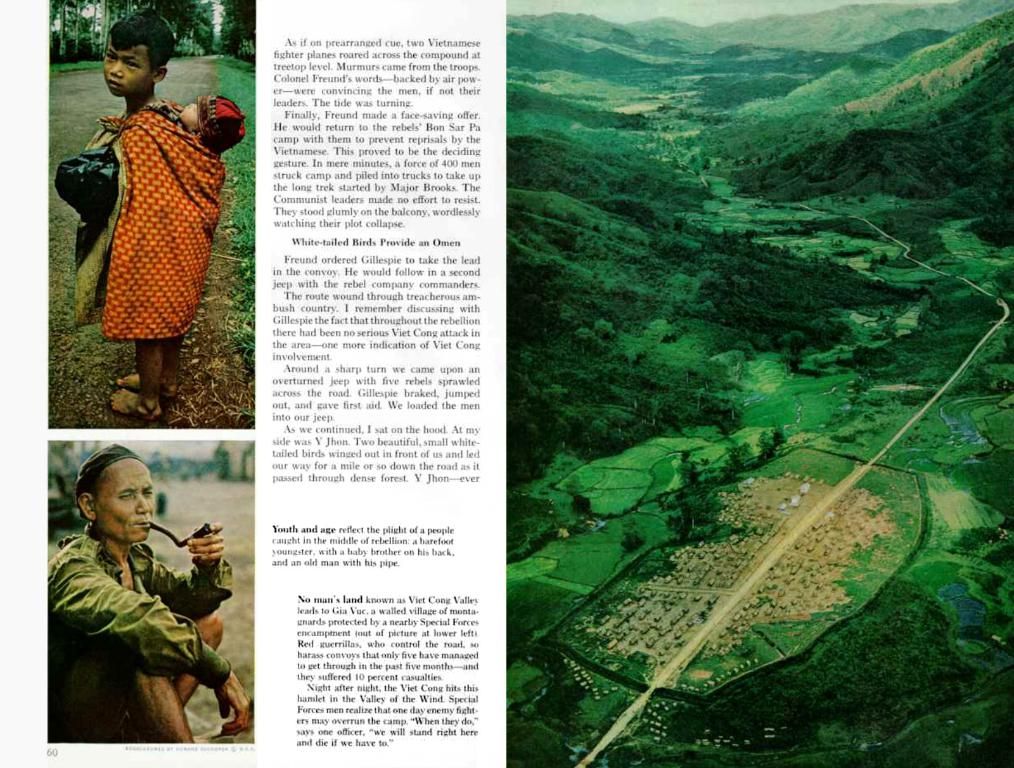

Welcome to the future, where the lines between the digital and physical worlds blur and the possibilities are endless. We're diving into Augmented Reality (AR) and its transformative impact on industries, specifically with regards to Industry 4.0!

AR: Blending Fact and Fiction

AR is a game-changer, powered by the merger of authentic images and computer-generated ones. This technology, often seen through glasses or a tablet's camera, overlays 3D graphics and data, making it indispensable for industries like medicine, military, architecture, and entertainment—and now, industry and automation!

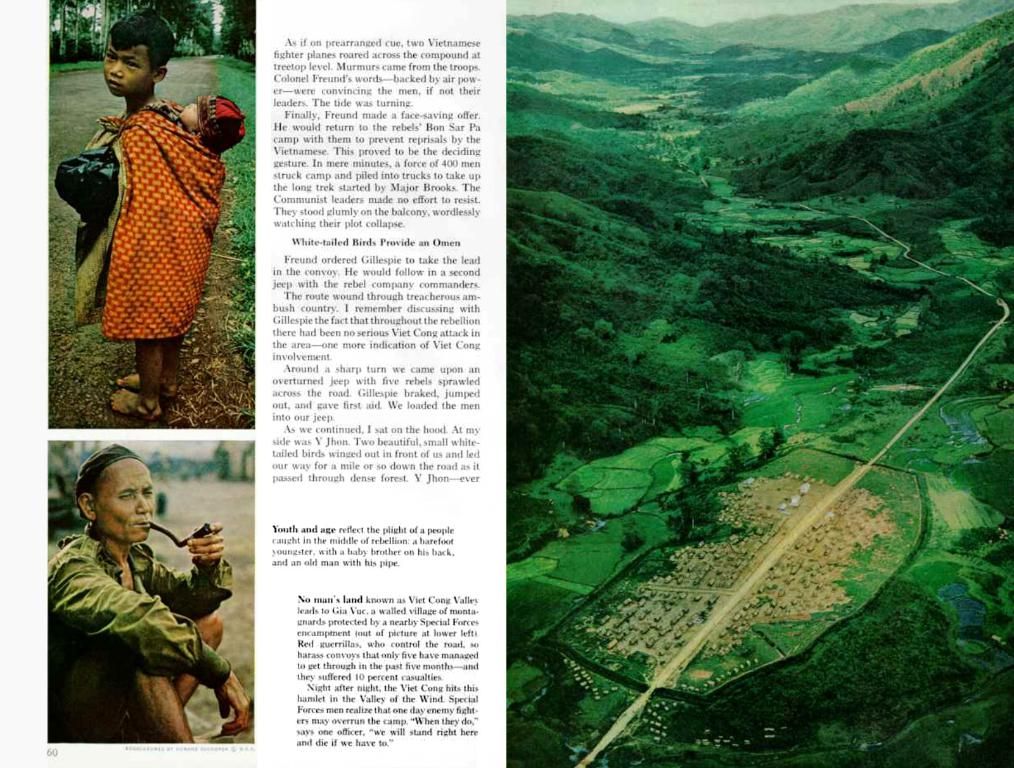

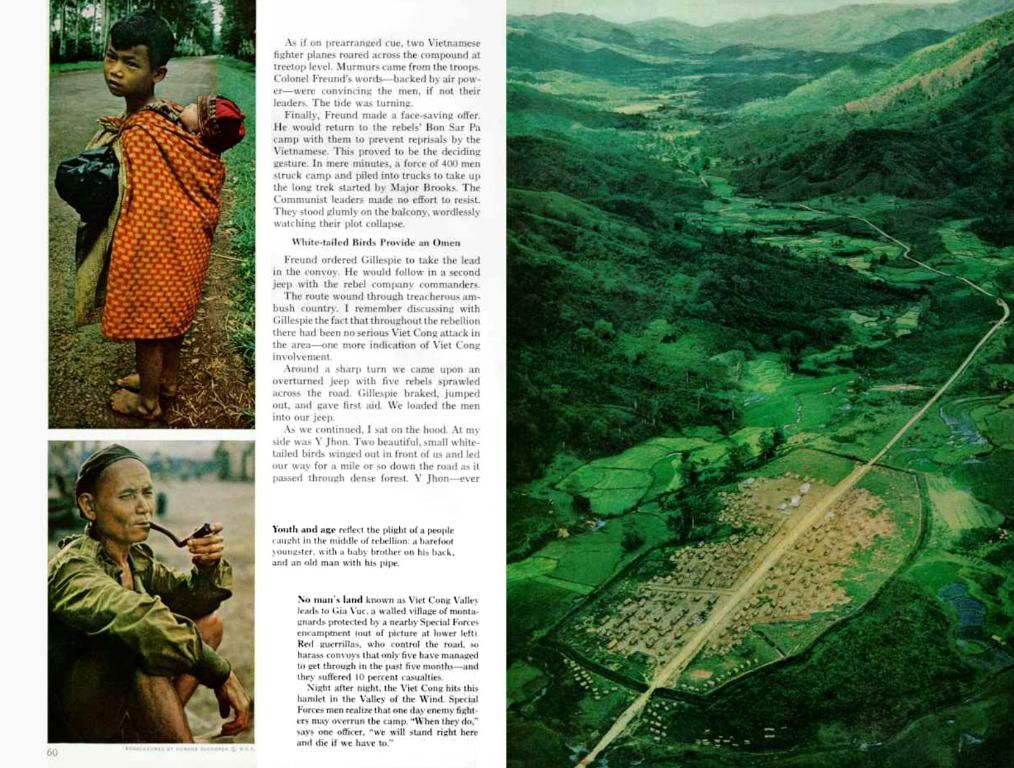

Industry 4.0: Smart Machines, Smarter Work

But what exactly is Industry 4.0? This term refers not just to advanced technology but new ways of working and people's roles within the industry. Essentially, Industry 4.0 is the unification of the physical world of production machinery with the virtual world of the Internet and information technology.

AR: The Unsung Hero of Industry 4.0

AR's unique blend of vision systems, image processing, data exchange with IT systems, and the display of complex information revolutionizes industrial enterprises. Here's how:

Empowering Communication

- Visual Aids: AR offers workers virtual instructions and information directly on real-world objects, simplifying complex data interpretation.

- Real-time Data: It delivers real-time insights and alerts, ensuring data availability without the need for separate systems.

Downtime Minimization

- Predictive Maintenance: AR identifies potential issues before they cause downtime, facilitating proactive maintenance.

- Prompt Problem Solving: By providing visual guidance, it aids in identifying and resolving problems quickly.

Expediting Skills Acquisition

- Innovative Training: AR delivers immersive and interactive training experiences, speeding up the learning curve for new workers.

- On-the-Job Support: Real-time guidance and feedback during tasks helps new workers master skills faster.

Intelligent Support

- Remote Troubleshooting: AR enables remote technicians to provide guidance, taking advantage of real-time communication and visual cues.

- Digital Manuals: It presents digital manuals and repair guides directly onto equipment, streamlining complex procedures.

Boosting Access to Knowledge

- Instant Insights: Workers have immediate access to digital resources and knowledge bases on the job site.

- Interactive Learning: AR provides interactive tutorials and training modules accessible directly on the factory floor.

Data Management

- Data Collection Automation: AR automates data collection, reducing manual reporting and ensuring accurate, up-to-date reports.

- Real-time Insights: By offering real-time data, it empowers managers and operators to make informed decisions based on current production metrics.

Virtual Training

- Realistic Simulations: AR creates realistic simulations for training purposes, making learning more effective and efficient.

- Personalized Learning: Training can be customized to meet specific needs or challenges, ensuring employees get the training they require.

Design Revolution

- Digital Prototyping: AR allows the creation of digital prototypes that can be superimposed onto physical environments, facilitating product design modification.

- Collaborative Design: It lets multiple stakeholders interact with digital models in real-time, improving design quality and reducing errors.

Streamlined Inspections

- Remote Evaluations: AR enables remote inspections, reducing travel requirements and expediting the inspection process.

- Real-time Feedback: It provides real-time feedback during inspections, catching issues early in the production cycle.

Join the AR revolution, and see your business reach new heights as Industry 4.0 transforms the way industries operate. It's time to embrace the future, and make the most of Augmented Reality's transformative potential!

Read more: The Magic of the Metaverse

Author: Rafał Siejca

Rafal, with over two decades of corporate experience and a decade as a VR expert, shares his insights as the CEO and CTO of a leading AR software company.

AR (Augmented Reality) technology, a blend of authentic images and computer-generated ones, is indispensable for industries like finance, business, and technology, especially in the context of Industry 4.0. This revolution in industrial enterprises empowers communication with visual aids and real-time data, minimizes downtime through predictive maintenance and quick problem-solving, expedites skills acquisition, and offers intelligent support via remote troubleshooting and digital manuals. By embracing AR, industries can leverage its potential to streamline inspections, design processes, and data management, propelling their operations into the future.